Fill off liquids - but do it safely

Never fill off dangerous liquids by directly pouring them out

Safety during bottling must be the number one priority

for your own personal protection!

Dangerous liquids must never be filled off by directly pouring them out. Even the use of a funnel does not provide the required degree of safety when bottling dangerous liquids.

- Increased accident risk by slipping on dirty floors.

- Skin diseases or poisoning by spilt chemicals.

- Health hazard from harmful vapours.

This means that purchasing a suitable pump for filling off hazardous liquids is an investment in the safety and health of your employees which pays for itself in a very short time.

Choosing the right pump

Apart from the size and type of the container, the required pump capacity and the suitability of the pump for the particular medium are important considerations for choosing the right pump.

The pump does not only have to be resistant to the medium to be bottled, but specific occupational safety and environmental protection regulations must also be considered.

Materials

The most suitable pumps are robust industrial pumps made from top-quality materials such as polypropylene (PP) for acids and alkalis, or stainless steel V2A (1.4301) for flammable liquids. We always recommend the use of PTFE seals.

Always check that the material is resistant to the medium to be pumped.

Container size and container type

Pumps that work according to the excess pressure principle are suitable for filling off the required quantities from canisters and drums. Air is pumped into the container using a pumping ball or pumping piston. This creates excess pressure in the container and the liquid is transported out via the immersion tube.

Barrel pumps are suitable for larger barrels and open containers. They draw in the liquid and then eject it. This family of pumps is characterised by their robust construction with a good pumping capacity and simple handling. Different immersion tube lengths mean that the pumps fit all the usual commercially available containers. Low-mounted suction valves ensure that almost all the residual liquid is removed.

Pump capacity

Electric pumps are the first choice for filling off large quantities at a fixed location. Their higher pumping capacity saves times and requires less manual effort. However, the purchase of an expensive electric barrel pump does not always pay for itself; there is often no on-site mains supply, e.g. in the open air, during assembly or in the equipment storage facility. Manual pumps are an interesting alternative to electric pumps for filling off small quantities due to their independence from a power supply and because they mean value for money.

Bürkle offers a wide range of pumping devices for manually removing liquids from containers, canisters, drums and tanks.

Container connections

In contrast to metal drums, which usually have an R2“ fine thread, there are no standard connection threads for plastic drums. There are basically two different ways of attaching the pump to the drum or container. On the one hand, the pump can be screwed onto the existing container thread using a barrel screw joint, possibly in combination with an adapter. On the other hand, universal solutions such as conical drum stoppers can be used.

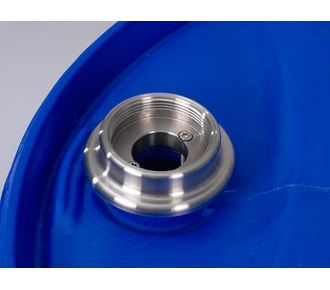

Brass barrel screw joint

Barrel screw joint made of nickel-plated brass for barrel pump stainless steel. Prevents electro-static charge in combination with the Anti-static set. For the safe transfer of flammable and easily flammable liquids. For containers with R 2" steel fine thread inside.

The container connectors make decanting even easier and safer with their more secure connection to barrels.

Gastight barrel connector

The gas tight barrel screw joint prevents hazardous gases from escaping from the barrel. G2" steel barrel thread, non-return valve with connection 1/8". Nickel-plated brass, seals made of FKM.

The container connectors make decanting even easier and safer with their more secure connection to barrels.

PP barrel screw joint

Barrel screw joint made of PP for secure connection in the barrel in three different thread models. For drawing off liquids that are not flammable.

The container connectors make decanting even easier and safer with their more secure connection to barrels. The connectors secure the pump in the barrel, enable a vertical position change and allow the required air exchange.

Container screw joint

Also for wide-necked screw caps. The screw joint 2" is screwed on from the inside using lock nut 2". (Mounting holes in the container 60 mm).

The container connectors make decanting even easier and safer with their more secure connection to barrels. The connectors secure the pump in the barrel, enable a vertical position change and allow the required air exchange.

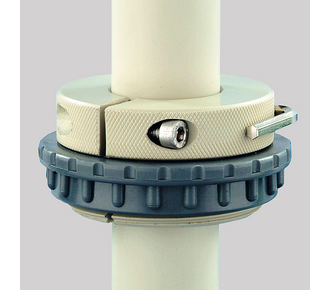

Universal thread adapter

Universal thread adapter for nearly all drums and other containers with opening of 48–75 mm in diameter, regardless of the respective thread. The thread adapter can be mounted quickly and easily with clamping screws and can be used for different container openings.

With G2" connector thread for Bürkle drum screw connections and pumps with immersion tube diameter up to 32 mm.

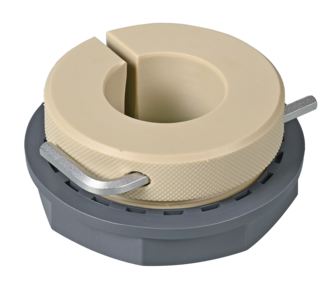

PVC barrel plug

Barrel bungs made of PVC, consisting of two parts, therefore can be used for various openings with a diameter from 40–70 mm.

Caution with filling aids

Siphons

Plastic siphons are a cost-effective alternative to mechanical pumps. Siphons are easy-to-use devices for safely filling off liquids from a higher container into a lower one. However, using them for aggressive or flammable liquids cannot be recommended. The pump bellows could be affected by acids and become brittle.

Liquids to be filled

Acids and alkalis

Acids, alkalis and detergents can be safely handled by plastic pumps made of PP or PTFE.

Bürkle offers many plastic pumps with both rigid discharge pipes and also with discharge tubing and shut-off valve for filling containers which are further away or higher up. When handling corrosive or aggressive liquids, the user must take appropriate precautions. Protective clothing such as gloves, goggles, aprons and face masks is essential.

PP barrel pump - discharge tube

PP barrel pump with rigid discharge tube.

PP barrel pump - discharge hose/stopcock

PP barrel pump with flexible discharge hose made of PVC, length of 1.2 m and stopcock.

PTFE barrel pump Ultrapure - discharge tube

Barrel pump with rigid discharge tube with stopcock made of PTFE.

PTFE barrel pump Ultrapure - discharge hose

Barrel pump with flexible discharge hose made of PTFE, length 1.2 m (65 cm for 5606-0401) and stopcock made of PVDF.

Flammable liquids

Filling off flammable liquids requires special precautionary measures. It is essential that filling devices for flammable liquids are made of conductive materials.

It is essential that any electrostatic charges formed are eliminated completely and without forming sparks. Stainless steel barrel pumps meet these requirements when the electrostatic charges are eliminated by using the Antistatic Set.

Solvent pump foot operated - discharge tube

Barrel pump for solvents with rigid discharge tube.

Solvent pump foot operated - discharge hose/stopcock

Barrel pump for solvents with discharge hose and stopcock made of stainless steel/PTFE.

Solvent pump hand operated

Hand-operated solvent pump for contaminationfree removal of organic solvents and flavouring agents. The hand pump works according to the overpressure principle. An excess pressure is built up in the tank with the pump ball, forcing the liquid out of the container.

Pouring flammable liquids

All medium-contacting parts are made of stainless steel AISI 304 (1.4301) and PTFE. The Bürkle anti-static set can be used to ground the pump for dispensing flammable liquids so that no electrostatic charge forms.

Gastight version

The pump can be completely closed off with the two ball valves so that no dangerous vapours can escape after dispensing.

Suitable for different containers

The hand pump is suitable for containers up to 60 litres.

Solvent pump hand operated, for tin-foil canisters

The solvent pump for tinplate canisters with pull-out spout puts an end to the risky decanting of dangerous substances into another container. The included thread adapter fits to the standard pull-out spouts - immediate safety!

Mini solvent pump

Dispensing system for solvents with discharge elbow

Dispensing system for solvents with discharge hose

Barrel pump stainless steel - discharge elbow

Stainless steel barrel pump - discharge hose & valve

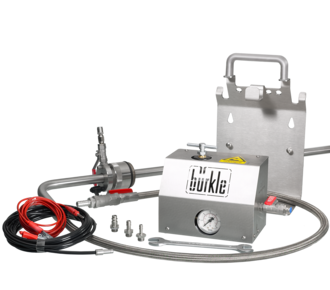

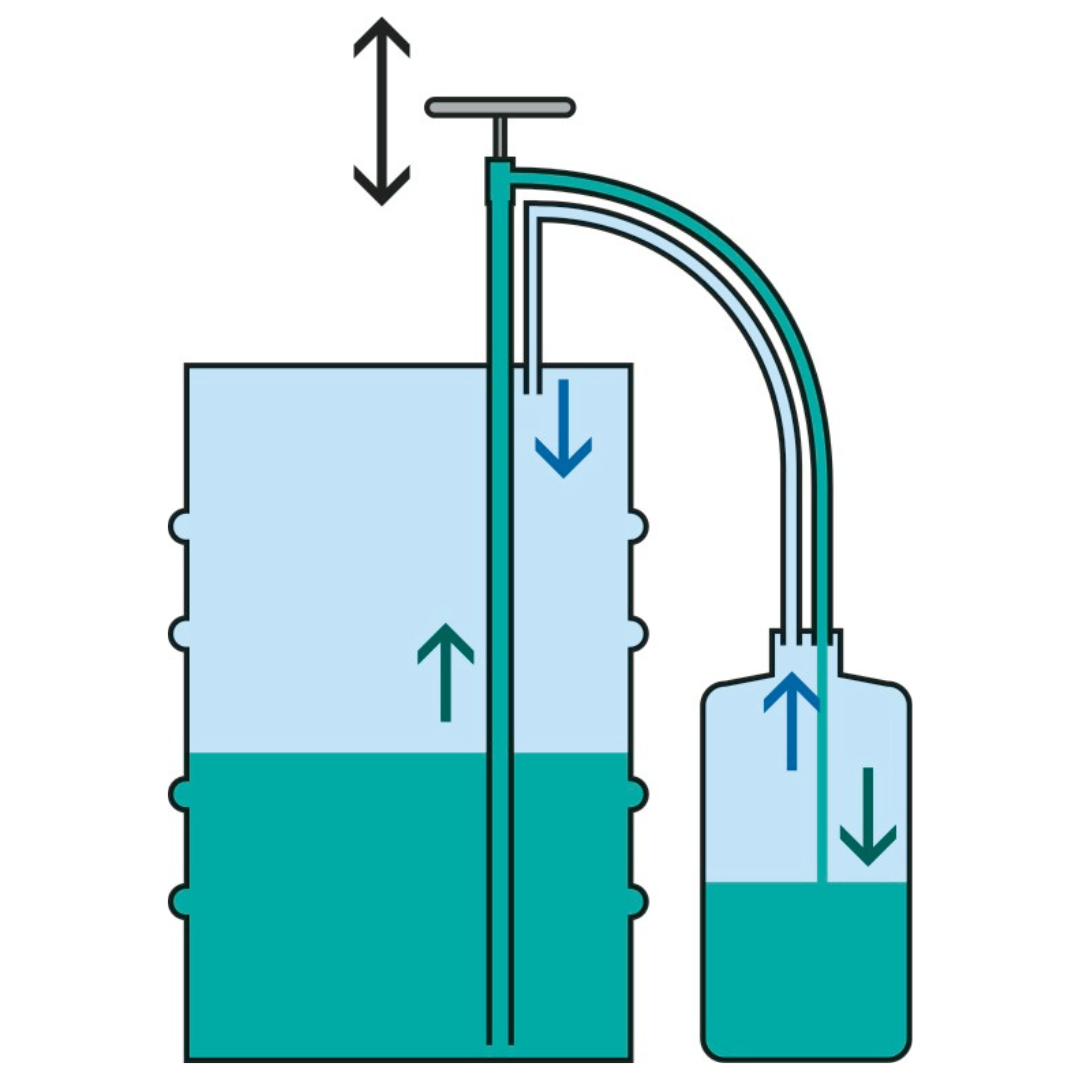

Gas-tight bottling

With volatile media, such as acetone or ammonia, hazardous vapours are formed in the container. Their evaporation into the working environment and the risk to the user can be reduced by using a gas-tight barrel connector. With particularly toxic, noxious and readily volatile media, a closed filling system with a gas-shuttle pipe is essential. In this method, the gases displaced from the container are returned directly into the original container. The harmful gases remain in the system; the greatest possible degree of safety during filling off is guaranteed.

Foodstuffs

If foodstuffs are to be filled off, then it must be ensured that the materials used are physiologically harmless. Materials such as stainless steel, polypropylene or PTFE, which also have a neutral taste and odour, can be recommended. Furthermore, the pump must be easy to clean.

Deutsch

Deutsch

français

français

español

español

русский

русский

italiano

italiano

日本語

日本語

Ελληνικά

Ελληνικά

polski

polski

português

português

português (Brasil)

português (Brasil)

Türkçe

Türkçe

中文

中文

한국어

한국어