KnowHow

On these pages, we provide everything worth knowing about samplers, about pumps for bottling dangerous liquids, as well as plastic lab equipment.

Chemical resistance of plastics and metals

Pay attention to the chemical resistance of materials!

The table "List of chemical resistance" and the information on chemical resistance in the respective product descriptions are based on data from various raw material manufacturers.

The values refer exclusively to laboratory tests with the raw materials.

Viscosity of liquids

The right pump for every liquid

Viscosity characterises the flow behaviour of a liquid. High viscosity means thick liquid, whereas low viscosity means thin liquid.

This "viscosity" of a liquid results from intermolecular forces, also known as internal friction. This internal friction decreases with increasing temperature and increases with decreasing temperature. The dynamic viscosity is given in Pas, for low-viscosity media in mPas.

Fill off liquids - but do it safely

Safety is the top priority

Never fill off dangerous liquids by directly pouring them out.

Purchasing a suitable pump for filling off hazardous liquids is an investment in the safety and health of your employees which pays for itself in a very short time.

Take samples - but do it right

How analysis produces the correct result

When taking samples, a random test is taken from an overall quantity. These samples serve as the basis for the analysis regarding quality assurance. The correct procedure for taking spot samples is therefore a very important subject.

Only with representative and authentic samples can reliable information about the quality, properties or composition of a particular material be provided.

About threads

How to determine thread sizes

Steel drums usually have standardised threads. This is different for plastic drums and containers, where there are a variety of thread types. We supply suitable adapters for the most common container threads so that outlet taps, pumps and other accessories can be securely fitted.

Packaging containers with UN approval

Transport dangerous goods safely without outer packaging

The person who fills a package with hazardous materials is responsible for its safety on dispatch.

In a UN approved container you can transport hazardous goods safely without having to repack them and thus save costs.

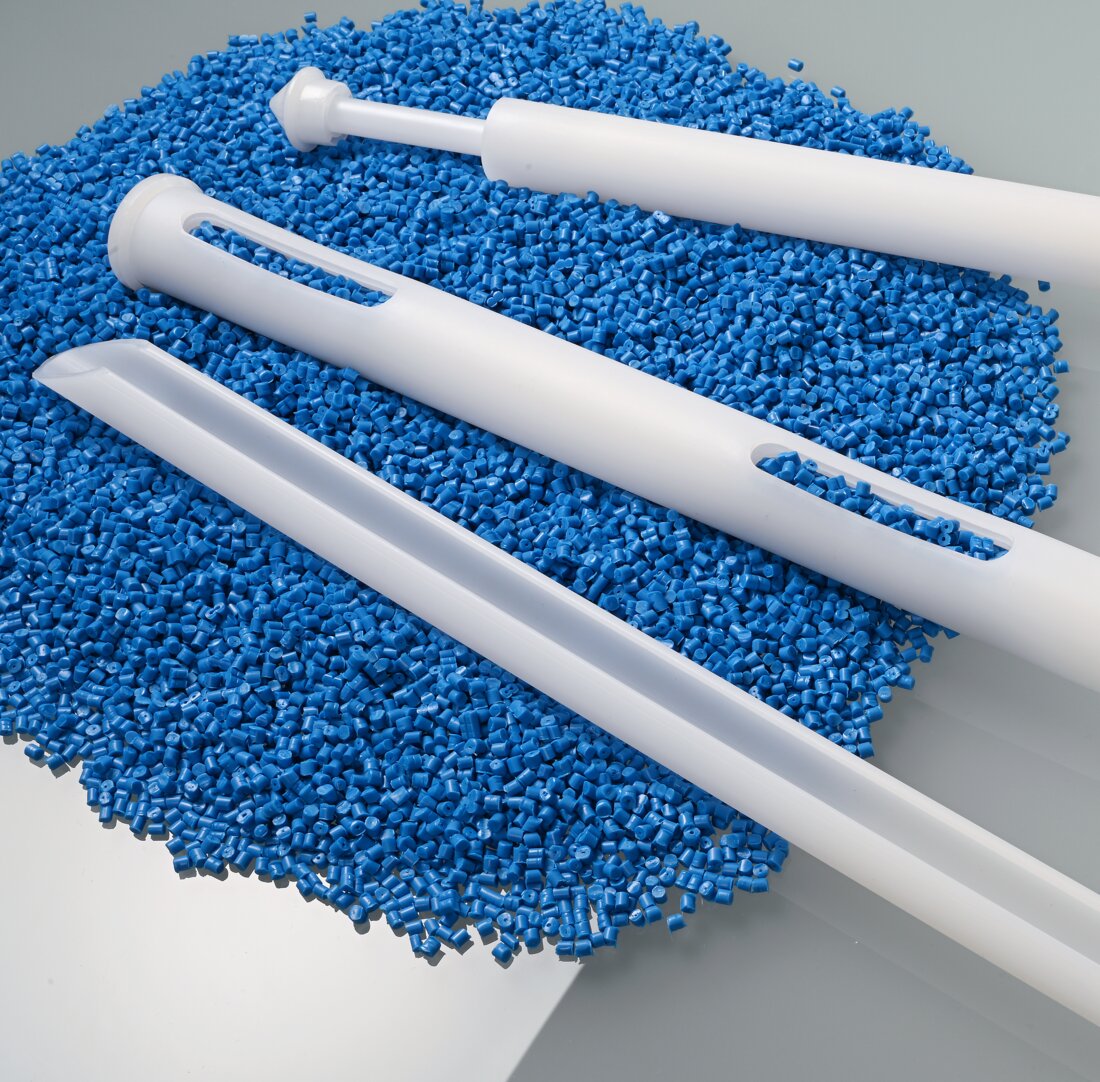

Disposable samplers

For the highest standards in sampling

In many application areas such as in the pharmaceutical sector, food & beverage branch or cosmetics industry, there are high standards for the sampler used to be free of particles and sterile so that the samples are not contaminated.

Disposable samplers can help to save time and costs and also ensure a correct analysis result in areas with high standards for sampling.

Bürkle Bio-PE Disposable Samplers with ACT Label

Sustainable Procurement in the Laboratory

Bürkle proves with its Bio-PE range that sustainability in the industry is more than just a buzzword and that even disposable products can have sustainable aspects.

From production to shipping, the company is committed to acting in an environmentally conscious way. This example shows how a holistic approach to sustainability can be successfully implemented.

Bürkle goes Bio

The purity of disposable products and ecological sustainability combined perfectly!

With our new LaboPlast® Bio and SteriPlast® Bio product lines, we offer products that fulfil all the properties required for high-quality sampling.

LaboPlast® Bio products are produced in a clean room from renewable raw materials, while SteriPlast® Bio products are additionally sterilised using gamma rays.

Our entire range of organic products carries the My Green Lab ACT certification.

Plastics and their properties

The table "Plastics and their properties" was compiled on the basis of information from various raw material manufacturers. The values refer exclusively to laboratory tests with raw materials.

Plastic parts made from these materials are often subject to influences that cannot be recognised in laboratory tests (temperature, pressure, material stresses, the effects of chemical substances, design features, etc.). For these reasons, the specified values can only serve as a guideline.

Gamma ray sterilisation

Our SteriPlast® products are sterilised by gamma rays, i.e. all micro-organisms contained within or adhering are killed off.

During irradiation, this energy is transferred to the electrons of the molecules of the products and in the process generates highly reactive radicals. This is why we speak of ionising radiation. These free radicals now break up the DNA of the existing micro-organisms so that they can no longer multiply and are killed off. The radiated product is therefore sterile.

Control seals with individual customer-specific special printing

close-it control seals

The close-it control seal has many satisfied users who use close-it as a control seal, for documentation or as an informative label.

We are happy to help you design your own close-it. Do you need final artwork for your draft? Or would you like to use our complete graphics service from draft stage through the print process? Our advertising department welcomes any challenge!

Advertise with your good name

Advertising media

Did you know that you can personalise some of our high-quality Bürkle products with your logo?

Whether it's company logos, instructions for use, advertising messages, content information or scales - there are no limits to your creativity.

Mounting litre scale

Sticking the scale on the container

The scale is self-adhesive and can be attached anywhere on the jerrycan. However, it is recommended to attach the scale to the side of the outlet spout.

You can find step-by-step instructions here:

Mounting Dosing pump Dosi-Pump

Fixing the pump to the container

We will show you step-by-step instructions on how to install the Bürkle-DosiPump correctly.

OTAL® liquid transfer pumps

Filling off liquids quickly, safely and cleanly

The OTAL® pump programme has now been established on the market for over 70 years. The pumps are known and appreciated for their easy handling in daily use.

Thanks to the simple stopper system, the OTAL® pump can be used for any standard container.

Deutsch

Deutsch

français

français

español

español

русский

русский

italiano

italiano

日本語

日本語

Ελληνικά

Ελληνικά

polski

polski

português

português

português (Brasil)

português (Brasil)

Türkçe

Türkçe

中文

中文

한국어

한국어