Carcasses reliably sampled

Containing microbial risks

Contamination by microorganisms can easily occur during the production of meat products. Appropriate hygiene measures as well as a suitable HACCP concept (Hazard Analysis and Critical Control Point) should prevent possible contamination. However, these measures cannot provide complete protection against micro-organisms. Microbiological contamination of meat products can only be monitored with professional sampling and analysis. The complete control of the product quality is therefore crucial.

Slaughter represents a particularly critical point in meat production. The risk of possible contamination is particularly high due to the animals themselves and the individual processing steps. In order to ensure slaughter hygiene, slaughterhouses must carry out regular microbiological tests on carcasses. Carcasses can be sampled with special stainless steel sample drills. With these, circular tissue samples can be taken quickly and easily from the carcass surface. Depending on the requirements, the samplers are available as manual or mechanical versions.

Food Hygiene

Meat production is a particularly sensitive area of the food industry. Finally, animals transmit pathogens such as salmonella and E. Coli, which can lead to serious infectious diseases in humans. In addition to direct contact with the animal, these bacteria are often transmitted via contaminated food. The meat processing industry must therefore eliminate contamination risks throughout the production process. The most important prerequisite for this is compliance with food hygiene. This includes all measures that are intended to guarantee a safe foodstuff, e.g. surface and equipment disinfection or personal hygiene. In combination with an appropriate HACCP concept, the safety of food should be guaranteed throughout the entire production process.

Despite all the measures taken, however, it can never be completely ruled out that a foodstuff may be contaminated by microorganisms. Regular sampling and analyses should provide early information about possible contamination.

Bacteria on carcasses

In the meat production sector, there is an increased risk, especially during slaughter, of micro-organism infestation. Due to its rich supply of nutrients and the high proportion of freely available water, meat is a good nutrient substrate for microorganisms. At the time of slaughter, the meat of healthy animals is germ-free. Only the slaughtering process and the further processing steps such as skinning and cutting pose a risk of contamination of the meat.

A large proportion of the micro-organisms are brought into the farm by the slaughtered animals themselves, for example via contamination of the fur and hooves or via the digestive tract. EU Regulations (EG) No. 2073/2005 and (EG) No. 1441/2007 define precisely which microbiological criteria must be met for a meat product. For example, in the case of carcasses of cattle, sheep, goats, horses and pigs, the aerobic mesophilic bacterial count and the bacterial count of enterobacteria must be determined in addition to salmonella.

Enterobacteriaceae are an indication of improper process control or faecal contamination. Escherichia coli (E. Coli) is one of the most important and well-known representatives of the enterobacteria. E. Coli is a natural component in the intestinal flora of humans and other mammals. Most strains of these bacteria are harmless, but some can cause serious diseases, such as the strain Enterohaemorrhagic Escherichia coli (EHEC). In most cases, infection with the EHEC strain is harmless and progresses with some nausea, abdominal pain and diarrhea. But there are also cases where an infection causes serious diseases, such as bloody intestinal inflammation (hemorrhagic colitis) or the hemolytic-uremic syndrome (HUS), which can lead to kidney failure. In the worst case, these diseases are even fatal.

EHEC strains are a natural component in the intestines of ruminants, e.g. cattle, sheep and goats. The bacteria are excreted with the faeces and carried into the environment. At slaughter, there is a risk that the carcase will be contaminated with EHEC through the fur soiled with faeces. Sampling shall be carried out regularly to ensure that carcasses comply with the microbiological criteria and do not contain bacteria of concern.

The destructive punching process

To test a slaughtered ruminant for micro-organisms, there are two common methods of sampling: the non-destructive swab method and the destructive excision method. In both procedures, several different sites are usually sampled per carcass. The number of samples as well as the ranges depend on the slaughter method used. Areas are selected where there is an increased possibility of contamination. In cattle, the pelvic canal, thighs, sternum or neck are often sampled. The timing of sampling shall be chosen on the basis of risk, for example immediately after the slaughter process.

For the non-destructive swab method, a swab is taken from the surface of the carcass. This is done by dabbing several times over a defined area with a swab soaked in a nutrient solution, depending on the requirements. The area varies according to the carcass and is 100 cm2 for larger animals such as cattle, pigs and horses and 50 cm2 for smaller animals. A stainless steel template limits the area provided for sampling. This procedure is repeated at all defined points.

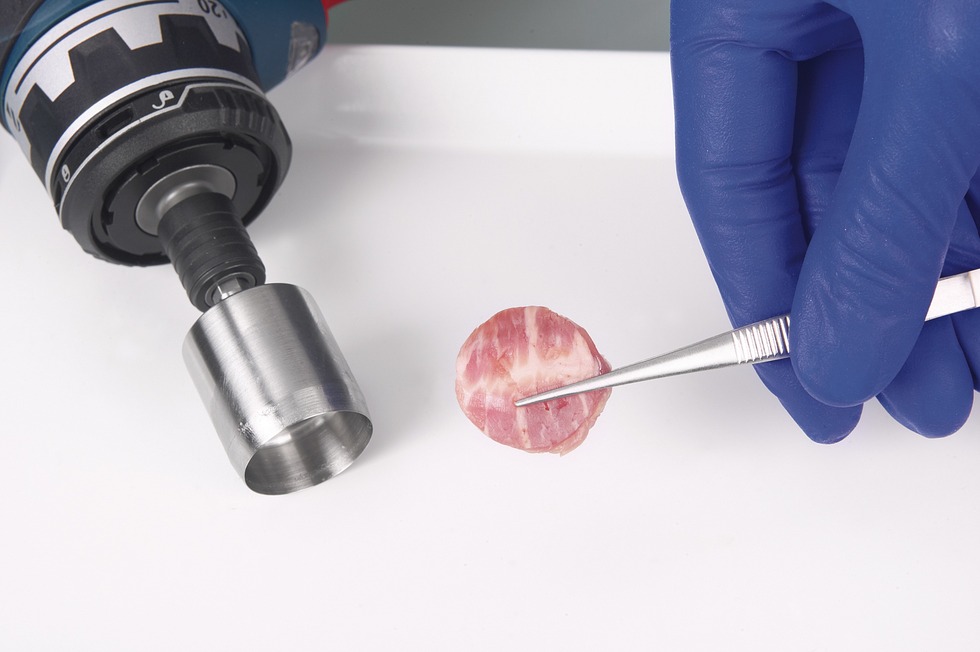

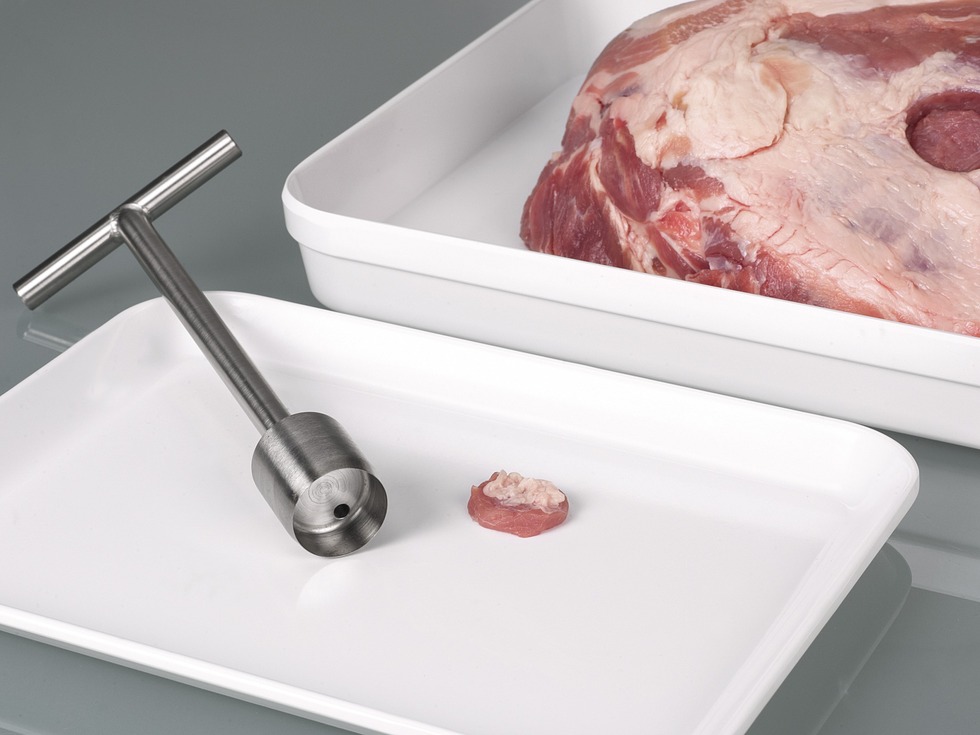

In the destructive cutting method, a piece of tissue with an area of 5 cm2 is removed from the carcass. The sample is taken either with a template or with a circular sample drill. When using the template, the piece of tissue is cut along the border with a scalpel and then removed from the carcass using a scalpel and tweezers. When using a sample drill, the tissue piece is punched out by screwing in the drill. The sample is then also removed from the carcass with a scalpel and tweezers. This process is also called destructive punching. The collected individual samples are finally combined into a composite sample.

Sampling of carcasses

The use of a sample drill, also called a cork drill, offers the advantage that the 5 cm2 area can be punched out precisely and quickly. Punching out with a drill is simple and straightforward for the user, as he only has to screw in the sample drill. Sample drills are available as manual versions, which are screwed in by hand, and as mechanical versions, which are screwed in using drills or cordless screwdrivers.

The BeefSteaker from Bürkle is a manual sampler especially for sampling carcasses. The circular head with the sharp cutting edge can be screwed into the surface quickly and easily. The rounded T-handle allows a comfortable handling of the sampler. The sharp stainless steel cutting edge makes it easy to cut out the sample. The sampler has a cut surface of 5 cm2. A hole in the crown prevents air compression and serves to eject the samples. The meat sampler is made of stainless steel 1.4404/1.4034 and is suitable for steam sterilisation or for sterilisation by flaming. For flaming, the sampler is first moistened with ethanol and then flamed for a few seconds with a gas burner. This method is quick and easy and can be performed directly at the sampling location without any problems. The manual sampler is ideal for use in smaller slaughterhouses, e.g. abattoirs or butcheries.

For larger slaughterhouses with densely sequenced sampling, Bürkle's drill head for carcass sampling is recommended. The drill head is similar to the BeefSteaker, but instead of the T-handle it has a hexagonal receptacle for bit holders or chucks, which is suitable for all conventional cordless screwdrivers or drills. The mechanical drive enables a fast and precise sample extraction. In addition, the drive guarantees fatigue-free working, even with rapidly successive sample collections. The material of the sampler is made of stainless steel 1.4034 and is also suitable for steam sterilisation or for sterilisation by flaming. The cut surface is 5 cm2 as with the BeefSteaker.

The drill head for carcass sampling and the BeefSteaker are ideal for regular microbiological testing of carcasses such as cattle, pigs, sheep, goats and horses and allow sampling according to DIN EN ISO 17604:2015-12, but the samplers can also be used in other areas, e.g. histology, medicine, food and beverage, cheese dairies or agriculture.

Conclusion

Regular microbiological inspections of the carcasses ensure slaughter hygiene. With a sample drill - either manual or mechanical - and the destructive punching method, tissue samples of carcass surfaces can be taken professionally and easily. On the basis of the samples taken, the carcass can be reliably examined for micro-organisms.

-

Article as PDF

Carcasses reliably sampled