Bürkle Bio-PE Disposable Samplers with ACT Label

Sustainable Procurement in the Laboratory

Laboratories play a crucial role in research and the development of new technologies. However, they also consume

a significant amount of resources and energy. For instance, according to the non-profit organization My Green Lab,

water consumption in laboratories is four times higher than in office spaces, and energy consumption is 5—10 times

higher. Furthermore, laboratories generate approximately 5.5 million tonnes of plastic waste annually.

Especially in sectors like pharmaceuticals and research, large global companies are increasingly recognizing their

responsibilities towards environmental sustainability. They aim to reduce their ecological footprint by introducing sustainability reports and programs. In the context of laboratories, where even minor contamination can have

substantial effects and where disposable products are often unavoidable, sustainable procurement plays a pivotal role in achieving these ecological goals.

Addressing this demand from scientists and procurement specialists, the non-profit organization My Green Lab has

developed the ACT Label. This label provides transparent, independently verifi ed information (Sustainable Management Management and Strategy Collaborative) regarding the environmental impact of laboratory products, making it easier for labs to source environmentally friendly products.

What is the ACT Label?

The ACT Label criteria, also known as the Environmental Impact Factor (EIF) criteria, were developed with input from industry experts and external stakeholders. Scientists, sustainability officers, procurement specialists, and manufacturers all provided valuable feedback on the EIF criteria, resulting in a comprehensive product labeling program for laboratory products.

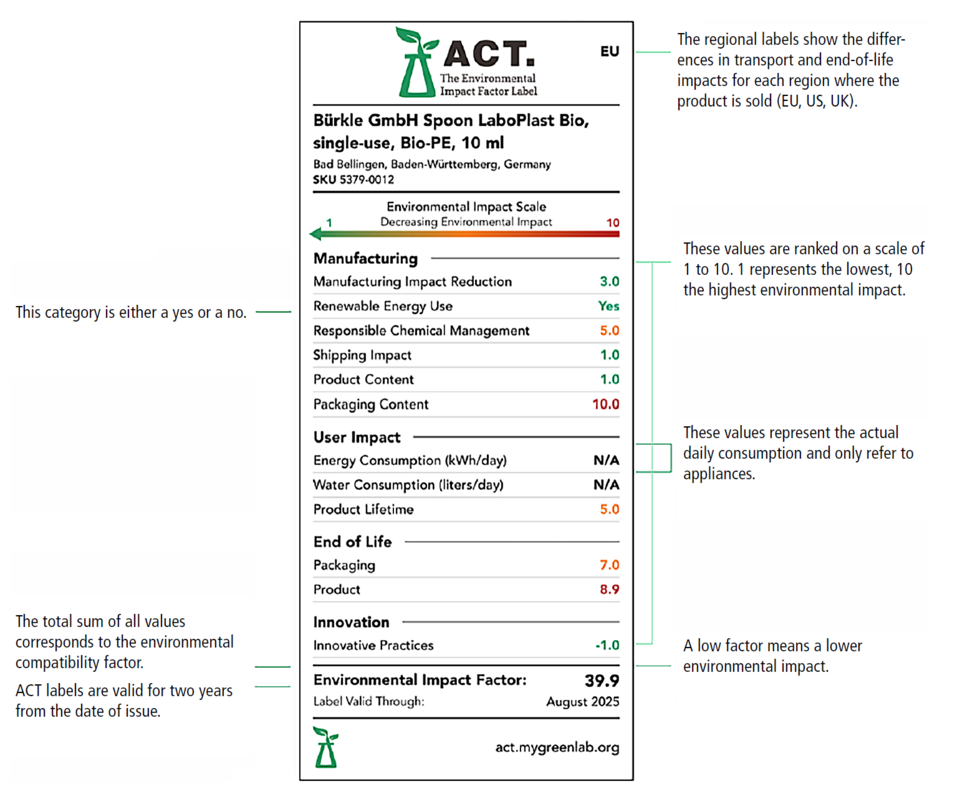

How to Interpret the ACT Label?

The ACT Label criteria were developed with input from industry experts and external stakeholders. Scientists, sustainability officers, procurement specialists, and manufacturers all provided valuable feedback on the criteria, resulting in a comprehensive product labeling program for laboratory products.

Scores on the ACT Label range from 1, indicating the lowest environmental impact, to 10, indicating the highest environmental impact. For equipment, the values for energy and water consumption represent the actual daily consumption and may exceed a value of 10.

Bürkle SteriPlast® and LaboPlast® Bio Disposable Samplers

The increasing demands for sampling in sensitive industries, such as pharmaceuticals, often necessitate the use of disposable products. However, given the growing environmental challenges, a rethinking becomes imperative. Bürkle has addressed this issue by offering an innovative alternative with its LaboPlast® Bio and SteriPlast® Bio disposable sampler range. The plastic used in the bio range is derived from components of the sugar cane plant, making it a renewable raw material.

Bürkle ACT Label Scoring Factors

Below, you’ll find detailed information about the individual scoring factors, ranging from the manufacturing process to

product disposal, and how Bürkle implements them.

Reducing the Manufacturing Impact

A critical step towards sustainable production involves minimizing the environmental impact of the manufacturing

process. Bürkle employs various measures, including transitioning to energy-efficient production models and employing a modern heating system. For example, the heating system is fed from a deep well through a heat exchanger, with process heat being recirculated.

Additionally, smaller measures within the value creation process contribute to achieving overarching goals. An example of such measures is the internal reuse of cardboard packaging initially used for transporting items to Bürkle.

These process optimizations lead to more efficient operations, reducing energy consumption and waste.

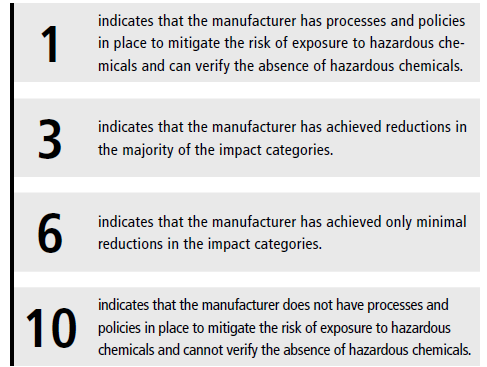

My Green Lab assesses practices and initiatives at production sites that contribute to reducing environmental impacts, rating them on a scale of 1 to 10.

Use of Renewable Energies

The utilization of renewable energies is another crucial step towards sustainability. Bürkle has firmly integrated

this approach into its production strategy. All products are manufactured at the Bad Bellingen production site,

exclusively relying on renewable energies. Bürkle combines the purchase of green electricity with a company-owned

photovoltaic system.

With over 1240 hours of annual sunshine, Bürkle’s 1000 m2 of solar modules on its company building’s roof in Bad

Bellingen helps reduce annual CO2 emissions by over 136 tonnes. By combining green electricity (100% hydroelectric power from the High Rhine) and self-generated electricity, Bürkle achieves 100% emission-free electricity consumption. This demonstrates the feasibility of resource-saving production.

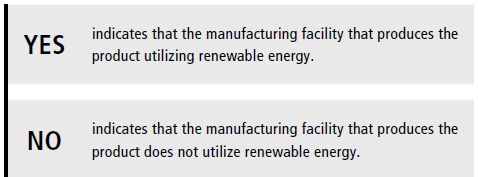

My Green Lab evaluates this factor with a “YES” if a corresponding green electricity contract exists for the company location.

Responsible Shipping

Shipping products can significantly impact the environment. Bürkle demonstrates considerate action in this

regard. The development, production, and distribution of Bürkle Bio-PE samplers all take place at the same location

in Germany. This setup enables short transport routes within the European market and eliminates the need for cargo

planes, leading to reduced CO2 emissions.

My Green Lab’s Shipping Impact assessment evaluates product transportation from the production place (e.g.,

Germany) to the destination (e.g., USA). The concept focuses on shorter shipping distances and applies to many

products, also considering the type of transport.

Lifetime of Product and Packaging

The fact that Bürkle Bio-PE samplers are disposable products contradicts the desired longevity and sustainability associated with Bürkle’s high-quality products. Sterile items, for instance, have a limited shelf life of two years from their manufacturing date. In line with the transparency principle of the ACT label, this limitation is evident in the rating and is unavoidable in this product category.

Sustainable Raw Materials

Bürkle adopts innovative approaches when selecting materials for its products. The LaboPlast® and SteriPlast® organic disposable samplers are made from organic PE derived from sugar cane. This choice constitutes a more sustainable alternative to fossil raw materials like petroleum. The bio-PE content, amounting to at least 94%, significantly

surpasses the industry average.

Innovation

In addition to the aforementioned categories, Bürkle goes beyond and actively participates in various programs aimed at reducing CO2 emissions. These include the GLS Climate Programme and forest conservation projects, which have already offset an impressive 17.339 tonnes of CO2. The company is also certified as climate-neutral.

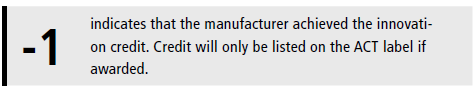

With this factor, My Green Lab encourages companies to make sustainable commitments that extend beyond the previously mentioned categories.

Summary

Overall, Bürkle proves with its Bio-PE range that sustainability in the industry is more than just a buzzword and that

even disposable products can have sustainable aspects. From production to shipping, the company is committed to

acting in an environmentally conscious way. This example shows how a holistic approach to sustainability can be

successfully implemented.

My Green Lab‘s View of Bürkle

“ACT promotes a life cycle approach to product sustainability, so I am pleased to see wider efforts to reduce product impact reflected in Buerkle’s first ACT labels.

Their efforts and achievements show that more sustainable products are viable whatever the size of the company.

We look forward to working further with Buerkle in the coming years, as we all collaborate to drive down supply chain impact in science.”

RAJ PATEY, BUSINESS DEVELOPMENT DIRECTOR, MY GREEN LAB

-

Article as PDF

Bürkle Bio-PE Disposable Samplers with ACT Label