AccuOne battery operated barrel pump

Battery pump for small quantities

- Ideal for regular filling of small quantities of liquids into small containers with narrow openings

- Unique flexibility - battery and power supply interchangeable

- Drive unit can be easily disconnected, allowing one drive for multiple pumping stations

- Excellent chemical resistance

- Cordless battery barrel pump - electric filling without power connection

Packaging unit

Piece

Please note

Pay attention to the chemical resistance of the materials! See also "List of chemical resistance"

Detailed information

The AccuOne battery-powered barrel pump offers full flexibility and independence from the power grid.

The electric barrel pump is equipped with a lightweight and powerful lithium-ion battery without memory effect with auto-stop function to protect against deep discharge. The strong battery power allows filling up to about 1500 l per charge.

The Bürkle drum pumps AccuOne and EnergyOne with unique hybrid system allow fast, flexible and convenient filling whenever and wherever you want.

The electric drum pumps for small quantities are equipped with two different power supply systems: AccuOne, powered by a high-performance rechargeable battery, or EnergyOne, with power cord for direct power connection.

Unique: the supply units are interchangeable!

The rechargeable battery or the power supply unit are removable by means of a clip closure and can be quickly and easily exchanged for each other. This means that AccuOne can also be operated with the power supply unit and EnergyOne with the rechargeable battery. With an exchangeable battery as an accessory, charging pauses are also eliminated.

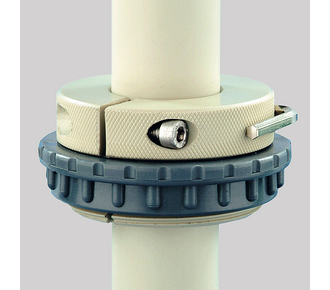

The drive can be easily separated from the pump unit with a clip closure. This allows filling from different containers at several stationary pump stations with one drive, without changing media and without having to clean the immersion tubes.

The immersion depth of up to 100 cm can be continuously adjusted, and the drum pumps achieve very good residual emptying of the filling containers.

The electric barrel pumps, which can be operated with one hand, can stand freely in the barrel or be attached to the container with a barrel screw fitting as an accessory.

AccuOne and EnergyOne are designed for applications where small quantities of liquid need to be filled into small containers with narrow openings.

The flow rate can be controlled continuously and precisely from 0.4 l/min to 12 l/min via the touch panel with dirt-, water- and dust-proof membrane keypad.

The lightweight and powerful drum pumps are made of the high-quality materials PP, PTFE and Hastelloy C and offer excellent chemical resistance. This makes them suitable for filling acids and alkalis, chemicals, cleaning agents, etc.

Typical application area of the product

Lightweight and powerful drum pump for small quantities e.g. in laboratories. Ideal for filling and transferring low-viscosity or aqueous acids, alkalis, chemicals, cleaning agents, etc. with a viscosity of up to approx. 200 mPas.

How to use the product

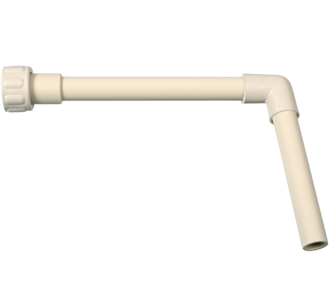

- Screw on the discharge elbow or discharge hose hand-tight.

- Fit the reducer and suitable threaded adapter or barrel plug (accessories) onto the delivery pipe of the pump unit.

- Insert the delivery pipe into the container and screw on the threaded adapter.

- The drive is supplied with power either via the rechargeable battery or the power supply unit. Attach the charged battery or power supply unit to the pump unit.

- Place a suitable, stable container under the outlet elbow or the hose.

- Switch the device to operating mode using the on/off button.

- Press the “+” button to increase the motor speed. Press the button until the desired flow rate is reached. Press the “-” button to reduce the flow rate.

- The drive is switched off by pressing the middle On/Off button again.

- Pumping station

- Drive

- Battery

- Charger with plug

- Plug adapter

- Fixed discharge elbow

Specifications

General material

PP

Polypropylene

Further materials

PTFE

Polytetrafluoroethylene

Further materials

Hastelloy C

Hastelloy 2.4610, AISI Alloy C-4

Throughput

- Delivery rate min.:

- 0.4 l/min

- Max. delivery rate:

- 12 l/min

Power supply

- Battery charging time:

- 4

- Plug:

- EU, UK

Pump outlet

- Outer outlet Ø:

- 16 mm (0.63 in)

- Length of discharge tube:

- 203 mm (7.99 in)

- Outlet type:

- Discharge tube

Delivery tube

- Immersion depth max.:

- 50 cm

Connection

- For openings from:

- 25 mm (0.98 in)

- Connection type:

- Barrel screw joint

Limit values

- Viscosity up to:

- 200

- Funding level:

- 4

Ø

- Immersion tube Ø:

- 25 mm (0.98 in)

Standards

- Protection class:

- IP 20

Coloring

- Color:

- gray

Filling container

- Adjusting the immersion depth:

- Immersion depth infinitely adjustable

- For containers up to:

- approx. 30 liters

How to fill

- Drive type:

- electric

- Pump type:

- Centrifugal pump

- Special features Pumps:

- Exchangeable outlet elbow/hose,Exchangeable battery/mains adapter,One drive possible for several pumping stations

Can be used either with rechargeable battery or power pack (both available as accessories).

All individual parts such as discharge bend, pumping unit or drive can be ordered separately. In addition to the discharge bend, a flexible discharge hose with nozzle is available.

With various barrel screw connections and thread adapters, the electric barrel pump can be fixed in all common containers.

No charging pauses, with an exchangeable battery as an accessory.

Complementary products

PP barrel screw joint

Barrel screw joint made of PP for secure connection in the barrel in three different thread models. For drawing off liquids that are not flammable.

The container connectors make decanting even easier and safer with their more secure connection to barrels. The connectors secure the pump in the barrel, enable a vertical position change and allow the required air exchange.

Container screw joint

Also for wide-necked screw caps. The screw joint 2" is screwed on from the inside using lock nut 2". (Mounting holes in the container 60 mm).

The container connectors make decanting even easier and safer with their more secure connection to barrels. The connectors secure the pump in the barrel, enable a vertical position change and allow the required air exchange.

PVC barrel plug

Barrel bungs made of PVC, consisting of two parts, therefore can be used for various openings with a diameter from 40–70 mm.

Battery without charger for Accu/EnergyOne

Charger for battery Accu/EnergyOne

Power supply unit with plugs for Accu/EnergyOne.

Replacement or exchange power supply for the electric drum pumps AccuOne and EnergyOne.

Drive without battery/power supply Accu/EnergyOne

Discharge tube, single, thread G 3/4"

Discharge hose 1.2 m (3.94 ft.), with nozzle

Cap

Closing cap with inner thread.

Pump station Accu/EnergyOne without drive

Similar products

EnergyOne mains operated barrel pump

Laboratory pump mains operated

Light- and high-performance pump to transfer watery media up to 300 mPas from canisters, barrels and narrow-necked containers from 32 mm opening diameter.

Drum pump for acids and alkalis

Barrel pump for weaker acids, such as phosphoric acid, chromic acid, battery acid, citric acid, etc.

Drum pump for concentrated acids/alkalis

Barrel pump for highly aggressive acids and alkalis, such as sulphuric acid, nitric acid, hydrofluoric acid, sodium hypochlorite etc.

Deutsch

Deutsch

English

English

français

français

español

español

русский

русский

italiano

italiano

日本語

日本語

Ελληνικά

Ελληνικά

polski

polski

português

português

Türkçe

Türkçe

中文

中文